Tanya engineering enterprise offers a comprehensive range of fabrication services, leveraging over two decades of industry experience and state-of-the-art infrastructure. We specialize in delivering customized solutions for both fixed and movable projects across various sectors, including highways and railways. Our commitment to quality, precision, and innovation ensures that we meet the diverse needs of our clients.

Light Fabrication

Our light fabrication services at Tanya engineering enterprise include the creation of smaller, intricate components that require precision and attention to detail. We handle projects such as custom brackets, enclosures, and panels, where accuracy is paramount. Our advanced machinery and skilled technicians allow us to produce complex parts with tight tolerances. We specialize in fabricating components from a variety of materials, including stainless steel, aluminum, and mild steel, ensuring the right material is used for each application. Additionally, our services extend to the production of decorative metalwork, signage, and prototype development, where aesthetics and functionality are equally important. Each project undergoes thorough quality checks to meet our stringent standards. With a focus on customization, we work closely with clients to understand their specific requirements and deliver tailor-made solutions. Our light fabrication services are ideal for industries such as electronics, automotive, and consumer products, where high precision and superior finish are crucial.

- Steel and Metal Frames

- Machinery Parts

- Custom Metal Fabrications

Heavy Fabrication

At Tanya engineering enterprise, we are equipped to manage large-scale fabrication projects, ensuring structural integrity and durability. Our heavy fabrication services encompass a wide range of capabilities. We specialize in the fabrication of structural steel components, including beams, columns, trusses, and frames essential for constructing bridges, buildings, and industrial plants. Additionally, we design and fabricate machinery platforms and industrial mezzanine floors, engineered to support heavy machinery and optimize vertical space in industrial settings. Our expertise extends to the creation of steel towers and chimneys, built to withstand harsh environmental conditions and ensure longevity. We manufacture storage tanks and pipelines for industrial use, adhering to safety and regulatory standards. Our capabilities also include fabricating components for pedestrian and vehicular bridges, as well as connecting structures like skywalks. Furthermore, we produce heavy-duty industrial equipment such as conveyors, trolleys, and bins designed for rigorous use. Recognizing the unique requirements of each project, we offer custom fabrication services, working closely with clients to design and produce tailored components. Our advanced facilities and experienced team enable us to handle the most demanding heavy fabrication projects, delivering products that combine structural integrity, durability, and precision to meet the highest standards of quality and performance.

- Industrial StructuresSteel

- Towers and BridgesHeavy-Duty

- Platforms and Mezzanines

Custom Fabrication

At Tanya engineering enterprise, we understand that each project is unique, which is why our custom fabrication services are tailored to meet the specific requirements of our clients. Our expertise in bespoke designs and prototypes allows us to create one-of-a-kind components and assemblies, ensuring that each product is crafted to precise specifications. We work closely with clients from the conceptualization phase through to final production, utilizing advanced CAD software and engineering techniques to bring their visions to life. Our custom machinery and equipment fabrication services cater to various industries, providing robust and reliable solutions designed to enhance operational efficiency and productivity. Whether it’s a specialized conveyor system, custom-built production line equipment, or unique machine components, we ensure that every piece is engineered for optimal performance and durability. Additionally, we handle specialty projects that require innovative approaches and advanced fabrication techniques. This includes complex assemblies, high-precision parts, and projects with stringent regulatory requirements. Our team of skilled engineers and fabricators is adept at tackling challenging projects, delivering superior quality and exceptional attention to detail. By offering comprehensive custom fabrication services, Tanya engineering enterprise ensures that our clients receive products that perfectly align with their specific needs and applications, driving their success in competitive markets.

- Bespoke Designs and Prototypes

- Custom Machinery and Equipment

- Specialty Projects

Welding and Assembly

Our skilled team at Tanya engineering enterprise provides expert welding and assembly services, ensuring strong, reliable joins and precise construction. Our welding capabilities include both automated and manual welding, allowing us to handle a wide range of projects with varying complexities. Automated welding systems ensure consistency and high-quality welds for large-scale production, while our experienced welders perform manual welding for projects requiring intricate, detailed work. Our component assembly services cover everything from small parts to large, complex assemblies, ensuring that each component fits perfectly and functions as intended. We conduct thorough quality inspections at every stage of the welding and assembly process, using advanced inspection tools and techniques to ensure that all joins are strong and components are assembled accurately. Our commitment to quality ensures that each project meets the highest standards of precision and durability, providing our clients with reliable, long-lasting products.

- Automated and Manual Welding

- Component Assembly

- Quality Inspections

Design and Engineering

Our design and engineering services at Tanya engineering enterprise ensure that your projects are planned and executed with the highest level of accuracy and efficiency. We offer comprehensive CAD modeling and drafting, utilizing advanced software to create detailed and precise models of your components and assemblies. This allows us to visualize and refine designs before production, ensuring optimal functionality and aesthetics. Our structural analysis services evaluate the strength and stability of designs, using state-of-the-art tools to simulate and test different conditions and loads. This ensures that our products not only meet but exceed safety and performance standards. Additionally, our project planning and management services provide a structured approach to your projects, from initial concept through to final delivery. Our experienced project managers coordinate every aspect of the project, ensuring timelines are met, budgets are adhered to, and quality is maintained throughout the process. By offering these integrated design and engineering services, Tanya engineering enterprise ensures that every project is executed with precision, efficiency, and excellence.

- CAD Modeling and Drafting

- Structural Analysis

- Project Planning and Management

Inspection and Quality Control

Quality is at the core of our operations at Tanya engineering enterprise. Our inspection and quality control services are designed to ensure that every product meets the highest standards. We conduct rigorous testing and inspections throughout the manufacturing process, utilizing advanced techniques and tools to identify and address any potential issues. Our commitment to compliance with industry standards means that all our products adhere to the strictest safety and quality regulations, providing our clients with peace of mind. We maintain comprehensive documentation and reporting for each project, offering detailed records of materials, processes, and inspections. This ensures full traceability and transparency, allowing clients to review the quality control measures applied to their products. By prioritizing quality in every aspect of our operations, we deliver reliable, high-quality products that meet the exacting demands of our clients.

- Rigorous Testing and Inspections

- Compliance with Industry Standards

- Documentation and Reporting

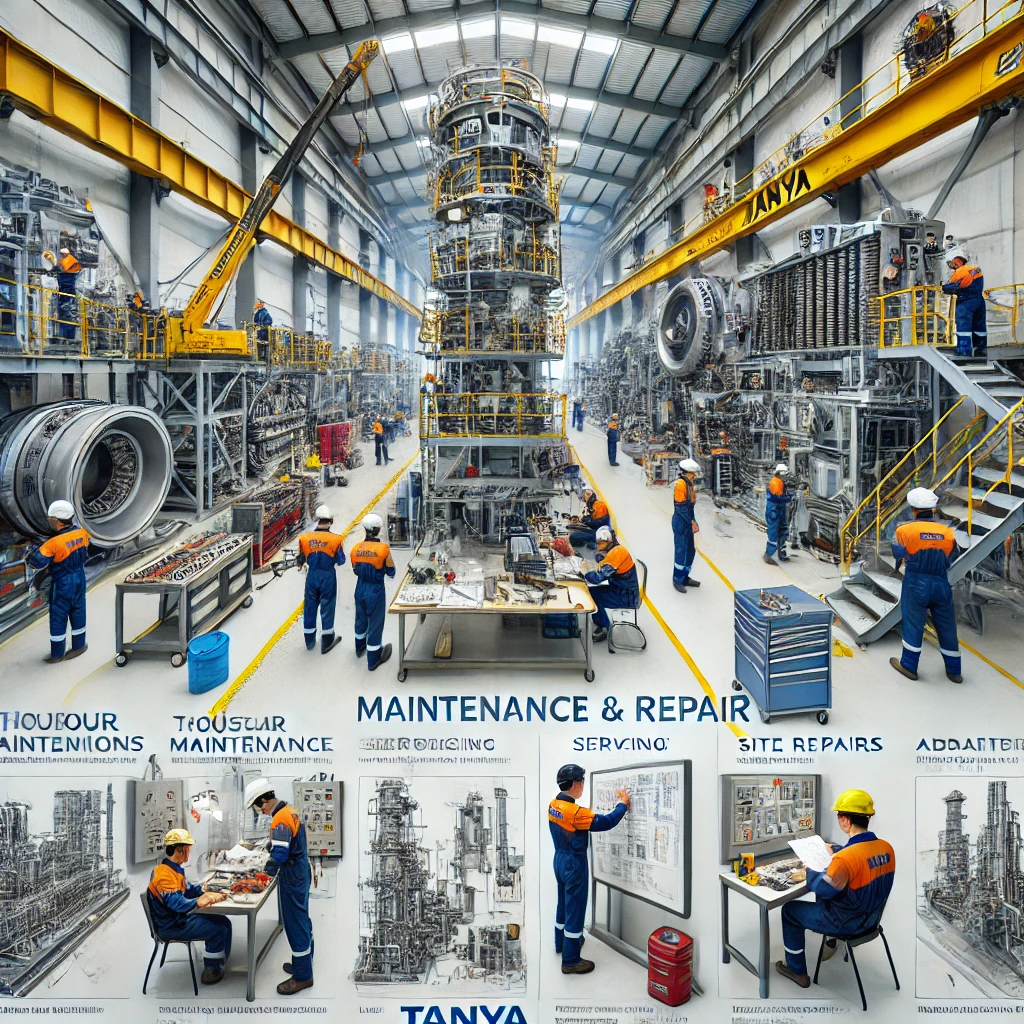

Maintenance and Repairs

At Tanya engineering enterprise, we provide ongoing maintenance and repair services to ensure the longevity and performance of your fabricated structures and equipment. Our services include regular maintenance checks, where we conduct thorough inspections and routine servicing to keep your equipment in optimal condition and prevent potential issues. Our team is equipped to perform on-site repairs, addressing any problems quickly and efficiently to minimize downtime and keep your operations running smoothly. Additionally, we offer upgrades and modifications to enhance the performance and extend the lifespan of your equipment. Whether it’s updating components, improving efficiency, or adapting your equipment to new requirements, our skilled technicians ensure that all modifications are carried out to the highest standards. By offering comprehensive maintenance and repair services, Tanya engineering enterprise helps you maintain the reliability and efficiency of your investments, ensuring they continue to meet your operational needs for years to come.

- Regular Maintenance Checks

- On-Site Repairs

- Upgrades and Modifications

Industries We Serve

We cater to a wide range of industries, ensuring that our expertise and services meet the specific needs of each sector. These industries include:

- Construction and Infrastructure: Supporting large-scale construction projects.

- Transportation (Highways and Railways): Fabrication for transportation infrastructure.

- Manufacturing and Industrial: Custom solutions for manufacturing processes.

- Energy and Utilities: Durable fabrications for energy and utility projects.

- Commercial and Residential Projects: Tailored fabrications for various building projects.

Why Choose Tanya Engineering?

- Experienced Team: Over 20 years of industry experience.

- State-of-the-Art Facilities: Equipped with advanced machinery and technology.

- Customized Solutions: Tailored to meet your specific project needs.

- Commitment to Quality: Rigorous quality control processes.

- Timely Delivery: Efficient logistics and project management.