Our state-of-the-art infrastructure, equipped with advanced machinery such as CNC machines, laser cutting machines, and robotic welding systems, allows us to manage orders of varying sizes and specifications efficiently. We have established a world-class production facility with high-volume production lines and custom fabrication units, enabling us to cater to both large-scale and unique client needs. Our rigorous quality control measures include in-house testing facilities and automated inspection systems to ensure products meet industry standards. Efficient supply chain management and spacious warehousing support timely procurement and storage of raw materials and finished products. Committed to sustainability, we implement eco-friendly practices and effective waste management systems. Our workforce, comprising experienced engineers, skilled technicians, creative designers, and dedicated support staff, benefits from continuous training and development programs and adheres to strict safety protocols. Additionally, our innovation labs and collaborations with industry experts drive our research and development efforts, keeping us at the forefront of market trends. This synergy between our advanced infrastructure and talented workforce enables us to produce superior products that meet the increasing demands of the competitive market, ensuring the highest quality and customer satisfaction.

Advanced Equipment at Tanya Engineering

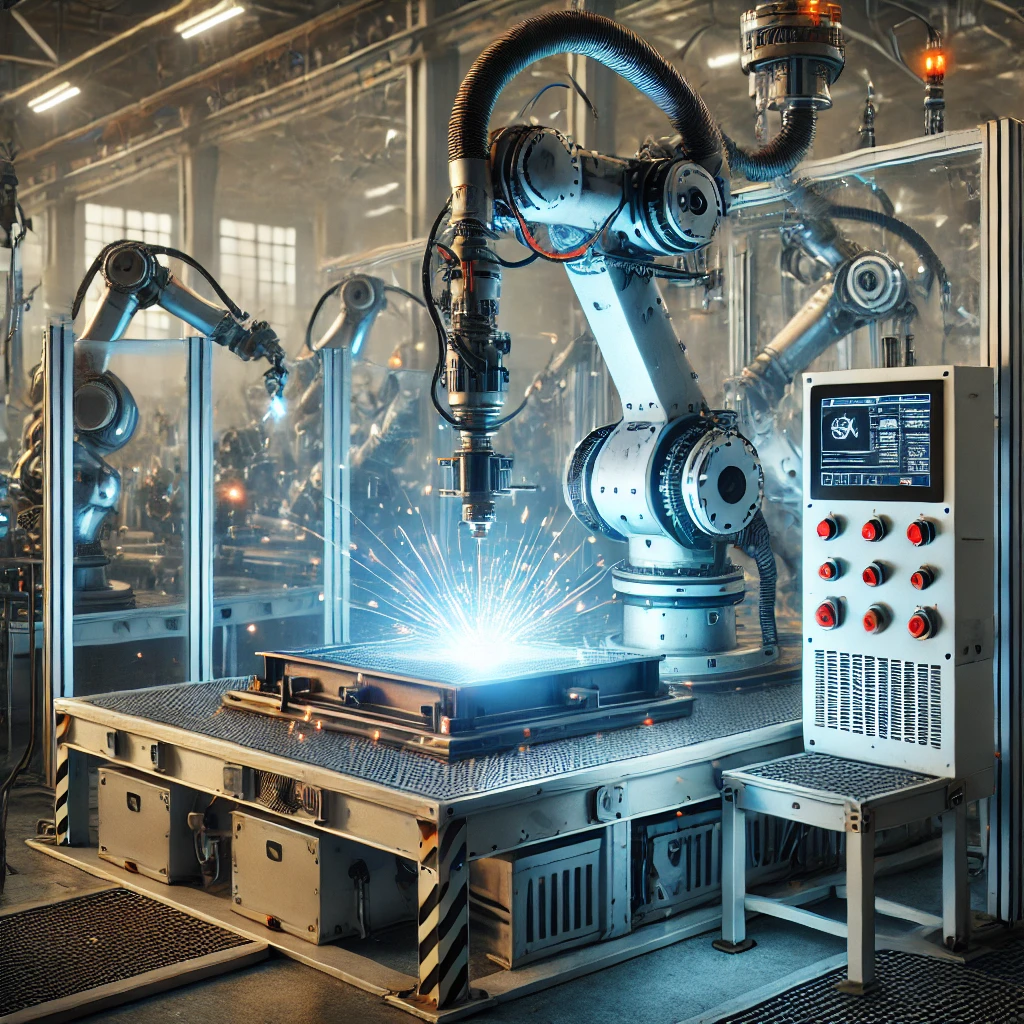

At Tanya engineering enterprise, we take pride in our state-of-the-art facility equipped with advanced machinery that ensures precision, efficiency, and quality in our fabrication processes. Our commitment to utilizing cutting-edge technology reflects our dedication to delivering superior products and services. Below is a detailed overview of our key equipment:

Our facility is equipped with high-precision Computer Numerical Control (CNC) machines. These machines are programmed with advanced software to automate the control of machining tools such as drills, lathes, mills, and routers. Key benefits of our CNC machines include: precision machining, ensuring each part is machined to exact specifications; consistency, with CNC automation each product is consistently replicated with minimal variation, ensuring high-quality standards; and complex geometries, the ability to produce complex shapes and intricate designs that would be challenging or impossible with manual machining.

We utilize advanced laser cutting technology for achieving high precision and clean cuts on various materials. Our laser cutters offer several advantages: high accuracy, laser cutting provides exceptional precision, allowing for tight tolerances and intricate details; smooth edges, the laser cuts leave clean, smooth edges, reducing the need for additional finishing processes; and versatility, capable of cutting a wide range of materials, including metals, plastics, and composites, making it suitable for diverse fabrication needs.

Advanced Equipment

Our facility includes cutting-edge equipment such as:

CNC Machines: For precision machining.

Laser Cutters: For high accuracy and clean cuts.

Automated Welding Stations: For consistent and strong welds.

Organized Production Floor

The layout of our production floor is designed to optimize workflow and reduce production time. We have separate zones for:

- Material Storage: Organized and easily accessible.

- Fabrication: Equipped with all necessary tools and machinery.

- Assembly: Dedicated areas to ensure efficient assembly processes.

- Finishing: For quality checks and final touches

Quality Control

At Tanya engineering enterprise, we have dedicated areas for quality control, ensuring that each product undergoes rigorous testing and inspection before delivery. Our commitment to quality is reflected in our stringent quality control processes, which are integral to our operations and vital to maintaining the high standards our clients expect. Our in-house testing facilities perform comprehensive tests on raw materials and utilize advanced measurement tools for precise dimensional inspections. Automated inspection systems, including non-destructive testing methods like ultrasonic and radiographic testing, and optical inspection with high-resolution cameras, detect internal and surface defects. Our quality assurance processes involve statistical process control to ensure consistency and quality, along with regular process audits to identify and mitigate potential issues. We adhere to international quality standards, including ISO certification, and customize quality control plans to meet specific client requirements. Detailed records of materials, processes, and inspections ensure full traceability, and we provide clients with compliance reports. Continuous improvement is a key focus, with feedback loops from clients and internal teams, and regular training sessions for our quality control personnel to stay updated with the latest industry standards and techniques. By implementing these robust quality control measures, Tanya engineering enterprise ensures that every product delivered to our clients is of the highest quality, reliable, and meets the stringent standards expected in the competitive market. Our unwavering focus on quality underscores our commitment to excellence and client satisfaction.

Logistics and Delivery

Our logistics team at Tanya engineering enterprise is well-equipped to handle both local and international shipments, ensuring the timely delivery of products to our clients. Our well-organized logistics area, featuring advanced inventory management systems, is always ready for shipments. We utilize state-of-the-art tracking technology to monitor the movement of goods in real-time, providing clients with up-to-date information on their orders. Our fleet of vehicles, along with partnerships with reliable shipping carriers, ensures that deliveries are made promptly and safely. Additionally, our team is skilled in managing customs documentation and compliance for international shipments, minimizing delays and ensuring smooth transit. We also offer flexible shipping solutions tailored to meet the specific needs of our clients, including expedited and scheduled deliveries. With a commitment to efficiency and reliability, our logistics and delivery processes are designed to provide seamless service, from our facility to the client’s doorstep.

Sustainability Practices

We prioritize sustainability and have implemented eco-friendly practices throughout our facility, including:

- Energy-Efficient Machinery: To reduce energy consumption.

- Waste Recycling Programs: To manage and recycle waste effectively.

- Carbon Footprint Reduction: Continuous efforts to minimize our environmental impact.

Continuous Improvement and Innovation

At Tanya engineering enterprise, we believe in continuous improvement and innovation. Our R&D department is constantly exploring new technologies and processes to enhance our capabilities and stay ahead of industry trends. This proactive approach ensures that we can meet the evolving needs of our clients and maintain our position as a leader in the fabrication industry.